QUALITY

At ALP Nishikawa, quality is the foundation of everything we do. Backed by TPM certification and reinforced by the technical expertise of our Japanese partners, our name is synonymous with precision, reliability, and operational excellence.

We deliver components that are not only zero-defect but also engineered for long-term durability and optimal performance. Through rigorous quality assurance at every stage of the manufacturing process—beginning at the design phase—we ensure each product adheres to our internal “First Time Right” philosophy while exceeding global industry standards.

Quality is engineered into every product, enabling our customers to build trust into theirs and drive innovation and efficiency across the entire supply chain.

Further strengthening our quality framework, advanced IoT integration and digitalisation enable real-time data monitoring, faster decision-making, and complete end-to-end traceability across all processes.

ALP Nishikawa operates ultra-advanced quality and testing laboratories across all its manufacturing locations. These facilities are supported by a centralised, fully equipped DSIR- and NABL-approved laboratory, enabling comprehensive testing and validation of both raw materials and finished products. Our quality teams ensure that every product consistently meets defined quality and performance requirements in line with customer specifications.

Our testing capabilities include weatherability, ozone resistance, and a wide range of product performance evaluations. For rigorous mould and dimensional validation, ALP Nishikawa employs advanced inspection and measurement systems such as Profile Projectors, 3D Coordinate Measuring Machines (CMM), Metallurgical Microscopes, and Surface Roughness Testers, ensuring precision, consistency, and reliability across all components.

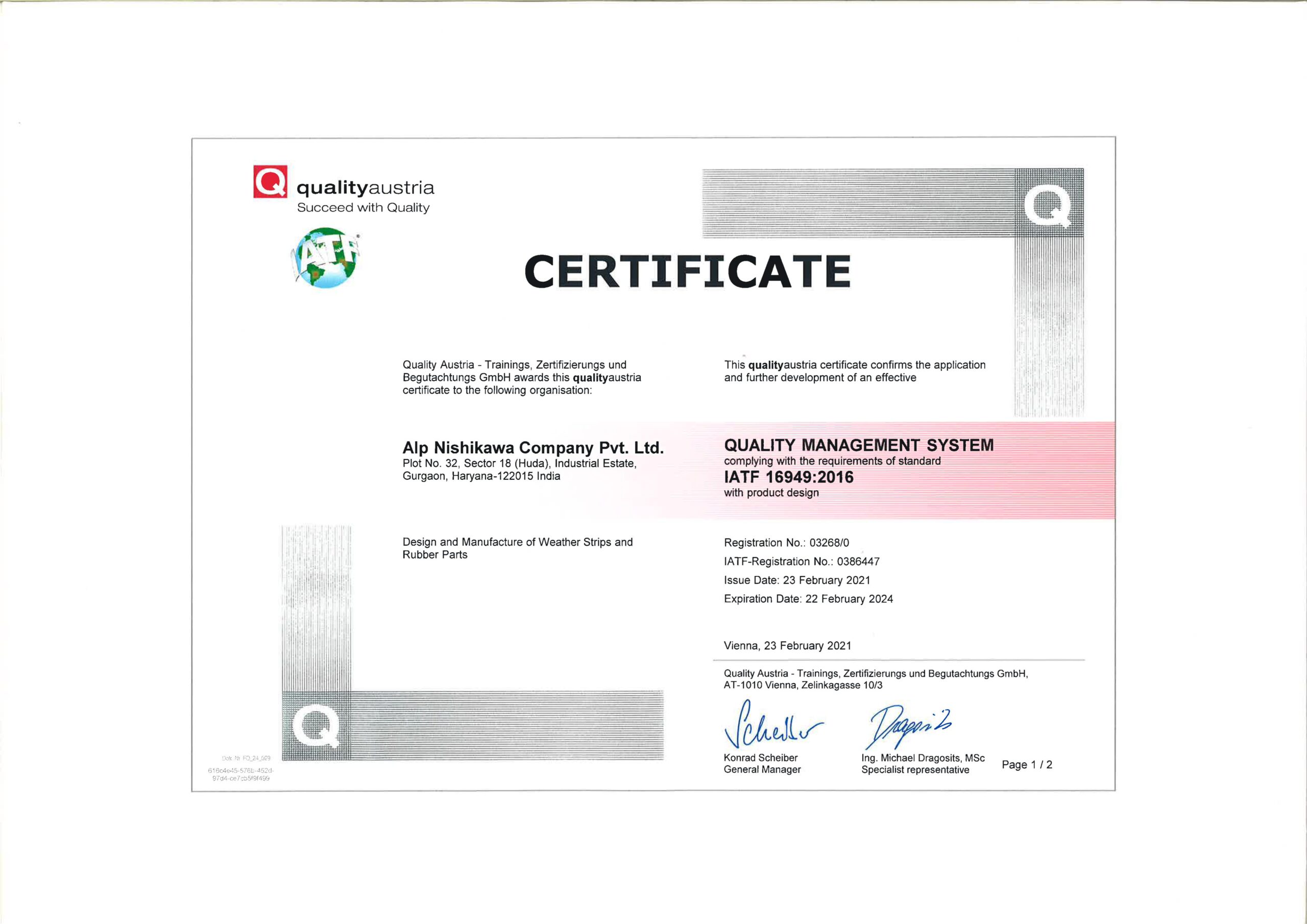

Certificates

ALP Nishikawa’s pursuit of perfection is driven by advanced technology and process excellence. Our unwavering commitment to quality is reflected in our consistent performance and long-standing partnerships with the global automotive industry. As a trusted OEM partner, we are certified to all major international standards, including TPM, IATF 16949, ISO 9001, ISO 14001, and ISO 45001.

These certifications are more than formal recognitions—they form the foundation of the precision, consistency, and reliability that enable our customers to build with confidence. We have consistently maintained PPM levels below 1, underscoring our strong focus on continuous improvement and operational discipline. Through strategic investments in automation and advanced manufacturing technologies, we continue to strengthen this benchmark, delivering enhanced quality, improved efficiency, and greater value across the entire supply chain.

QMS 9001

IATF 16949

HEALTH & SAFETY 45001

ENVIRONMENT 14001