Design & Development

D&D holds primary importance towards assisted and focused growth. For this, ALP Nishikawa has an ultra-modern Design and Development centre with self-invented methodologies for optimal reinforcement of structures, digital design and manufacturing of reinforced rubber products.

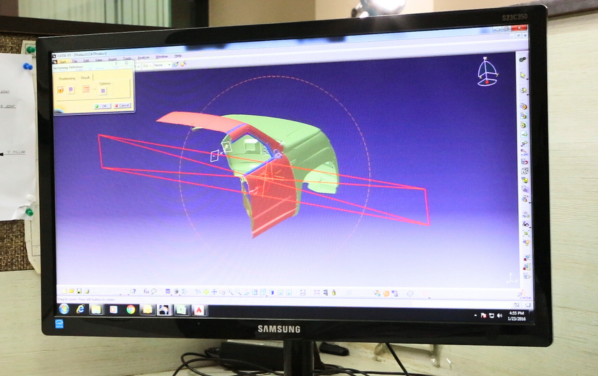

The design capabilities are fulfilled with the use of advanced software like Creo Parametric (Pro E), Catia), Abaqus, Hypermesh, AutoCAD, etc. along with facilities for conducting testing and validation checks. The company strives hard for new product development, betterment in existing products, Formulations of newer rubber materials, cost reductions by adopting advanced technology and designing capabilities.

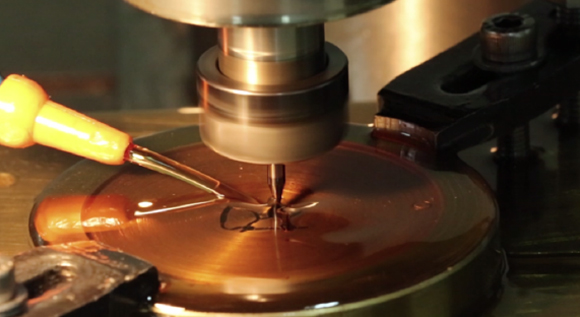

Tool Room

ALP Nishikawa is a completely self-sufficient entity. The principal reason it delivers optimal quality products lies in the company’s strict control on all subsidiary processes. The company has setup a modern tool room assisting in preparation of all cavities and moulds. The tool room is equipped with latest Vertical Milling Centres and EDMs.