DESIGN & DEVELOPMENT

ALP Nishikawa has recently established a state-of-the-art Research & Development facility at its primary manufacturing site, which produces over 100 million meters of weatherstrips annually for leading Indian and global OEMs. The R&D center is approved by the Directorate of Scientific and Industrial Research (DSIR) and is designed to provide advanced, forward-engineering support for evolving automotive sealing requirements.

Advanced Testing Facilities:

The Centre is equipped with a comprehensive suite of advanced testing capabilities designed to support quality, performance, and compliance across a wide range of applications. These facilities include:

- Spectroscopic Analysis for detailed material characterisation and enhanced aesthetic evaluation

- Climatic Chamber Testing with programmable temperature cycles from –40°C to 150°C and humidity control ranging from 30% to 90%

- Compression Load Testing to assess sealing performance under applied forces

- Gloss Measurement to ensure surface finish consistency and visual quality

- Flammability Testing in accordance with applicable automotive safety standards

- Physical and Chemical Testing of rubber compounds for material validation

- Dispersion Analysis to confirm uniformity and consistency of material properties

- Microscopic Coating Thickness Measurement with micron-level precision

- Coefficient of Friction Analysis for evaluating material interaction and performance

- Sliding Resistance Testing for glass run channel applications

- Vibration Testing to validate durability and performance under dynamic conditions

Design & Development

Tool Room

ALP Nishikawa operates as a fully self-sufficient organization. The company’s strict control over all subsidiary processes is central to delivering optimal quality products. We have set up a modern tool room to support the preparation of cavities and moulds. It is equipped with the latest vertical milling centres and EDM machines.

Advanced R&D Center for Automotive Engineering Innovation

Our R&D infrastructure supports the entire product development lifecycle from concept engineering and CAE-driven design optimization to prototype development, validation, and comprehensive performance testing. Core technical competencies include polymer and elastomer formulation development, material characterization, process optimization, durability and functional testing, and failure analysis, all conducted in alignment with global automotive standards and stringent OEM requirements.

Driving Patent-Led Innovation

Innovation and intellectual property creation are integral to ALP’s R&D culture. The organization has established structured innovation systems, advanced laboratory infrastructure, and cross-functional engineering teams to accelerate ideation, technology development, and systematic patent generation.

This focused approach has resulted in a significant expansion of ALP’s patent portfolio. Patent registrations have grown from one patent in the previous financial year to seven patents in Financial Year 2025, reinforcing ALP’s commitment to technology leadership and the development of proprietary automotive solutions.

Innovations by ALP Nishikawa

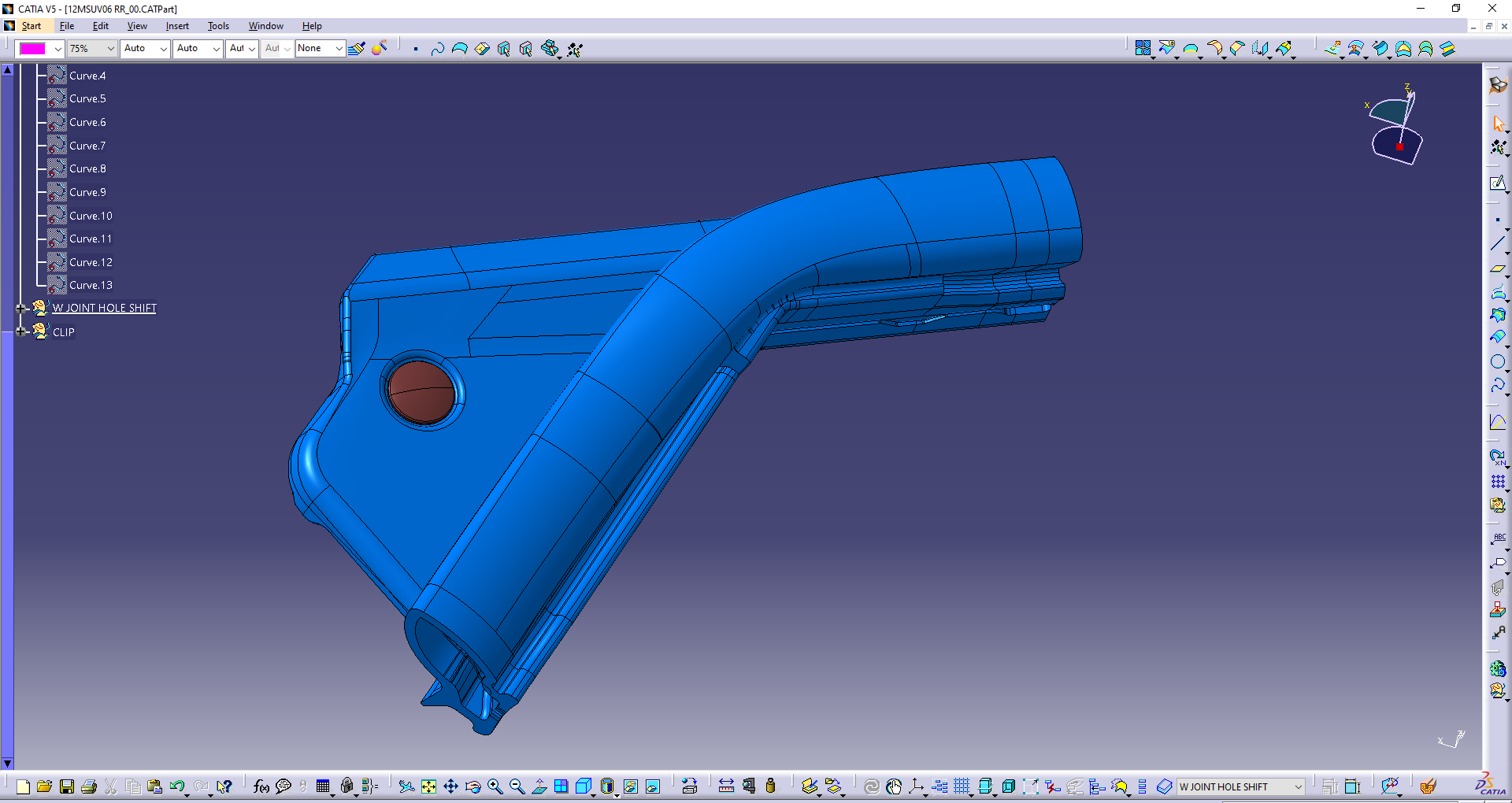

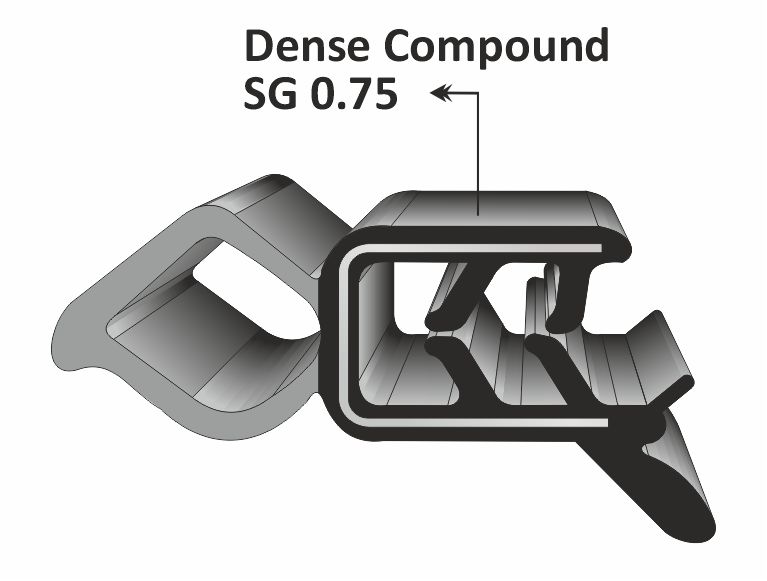

Weight reduction by reducing specific gravity of dense compound from 1.25 to 0.75

Cost reduction by replacement of Butile sealant with ultra low specific gravity sponge

Colored door seals for premium vehicle

Corner molding of main seals/ sub seals with thermoplastic for improved productivity

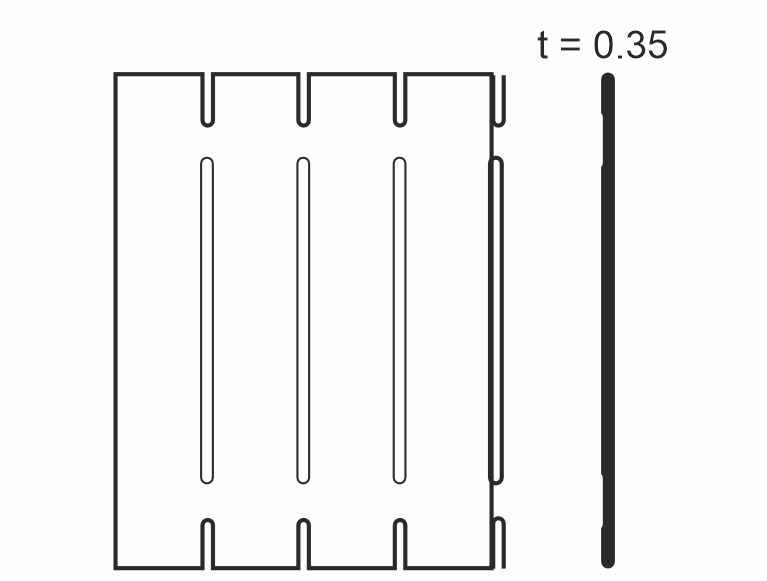

Weight reduction by reducing thickness of core metal from 0.5 to 0.35mm

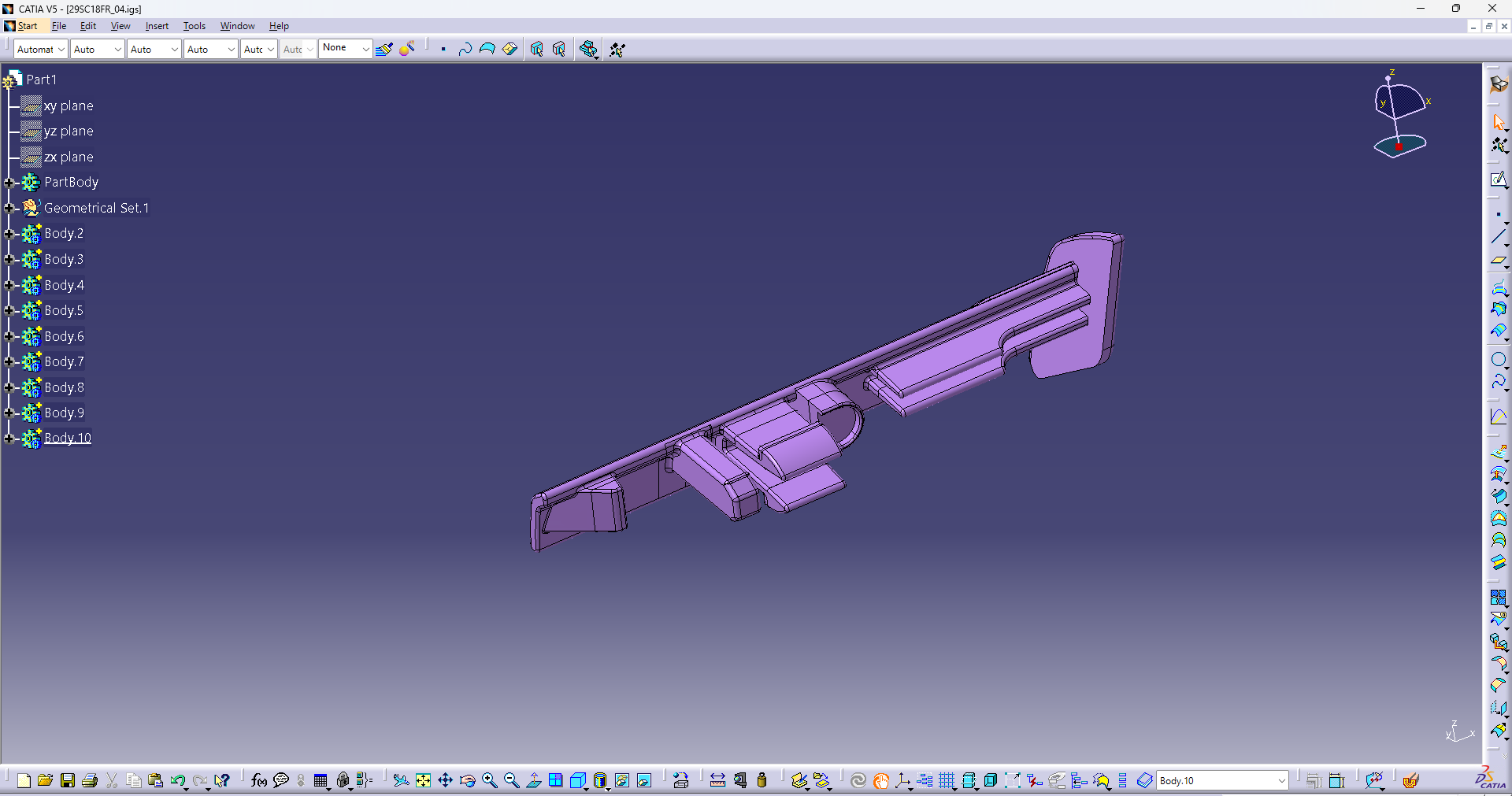

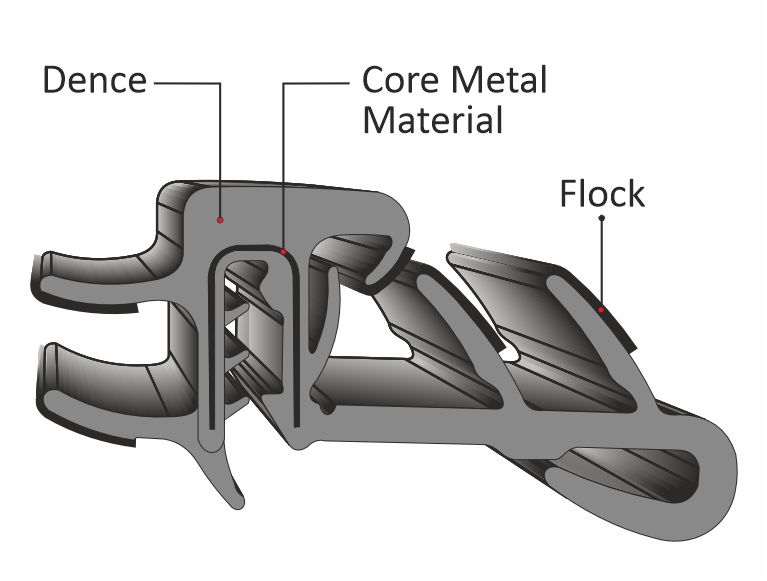

Cost reduction by replacement of imported aluminium core with special designed CRC Metal in hybrid glass run