Innovating for customers, value creation, and people empowerment worldwide.

Engineering Excellence in Sealing & Plastics

ALP Nishikawa

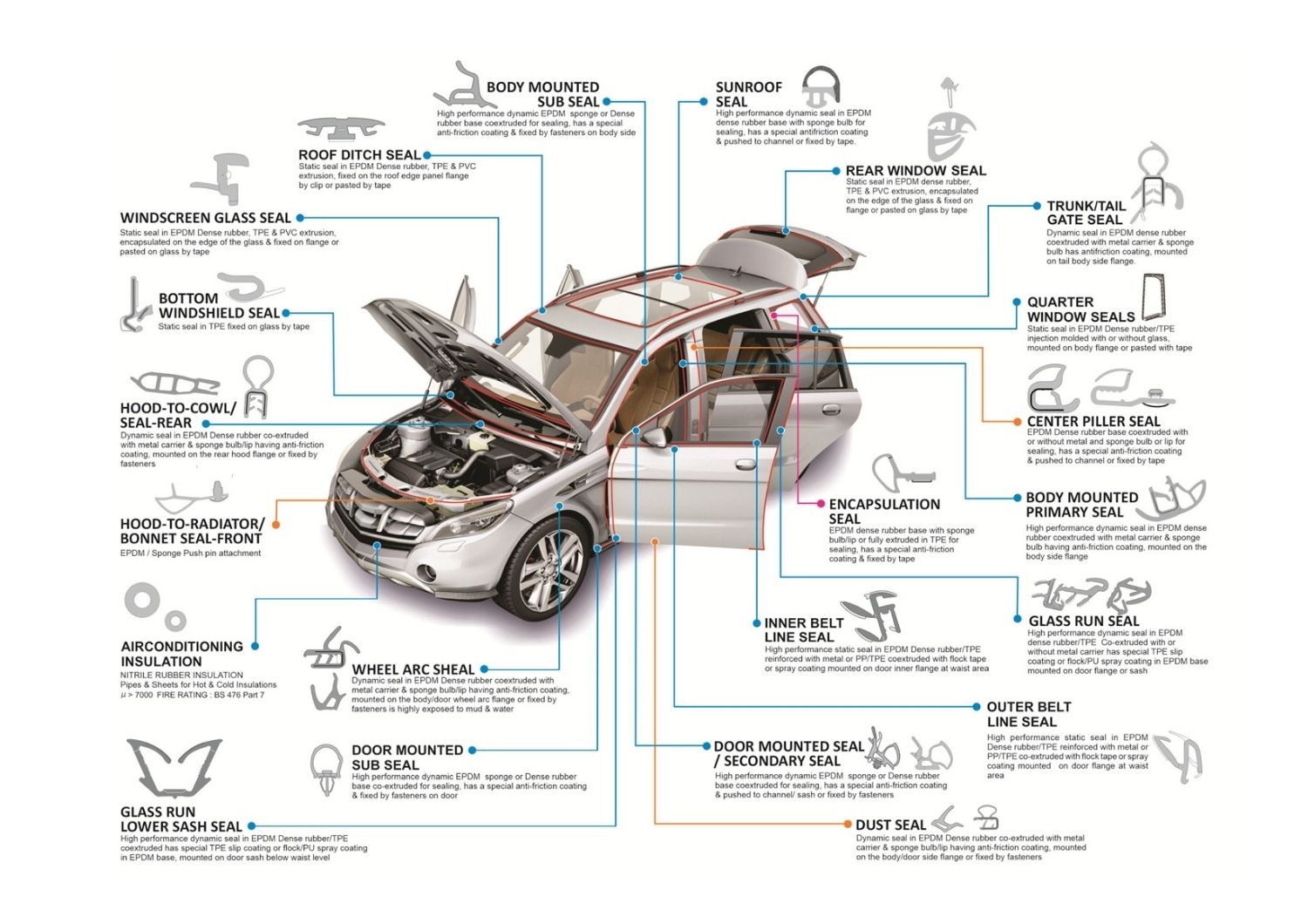

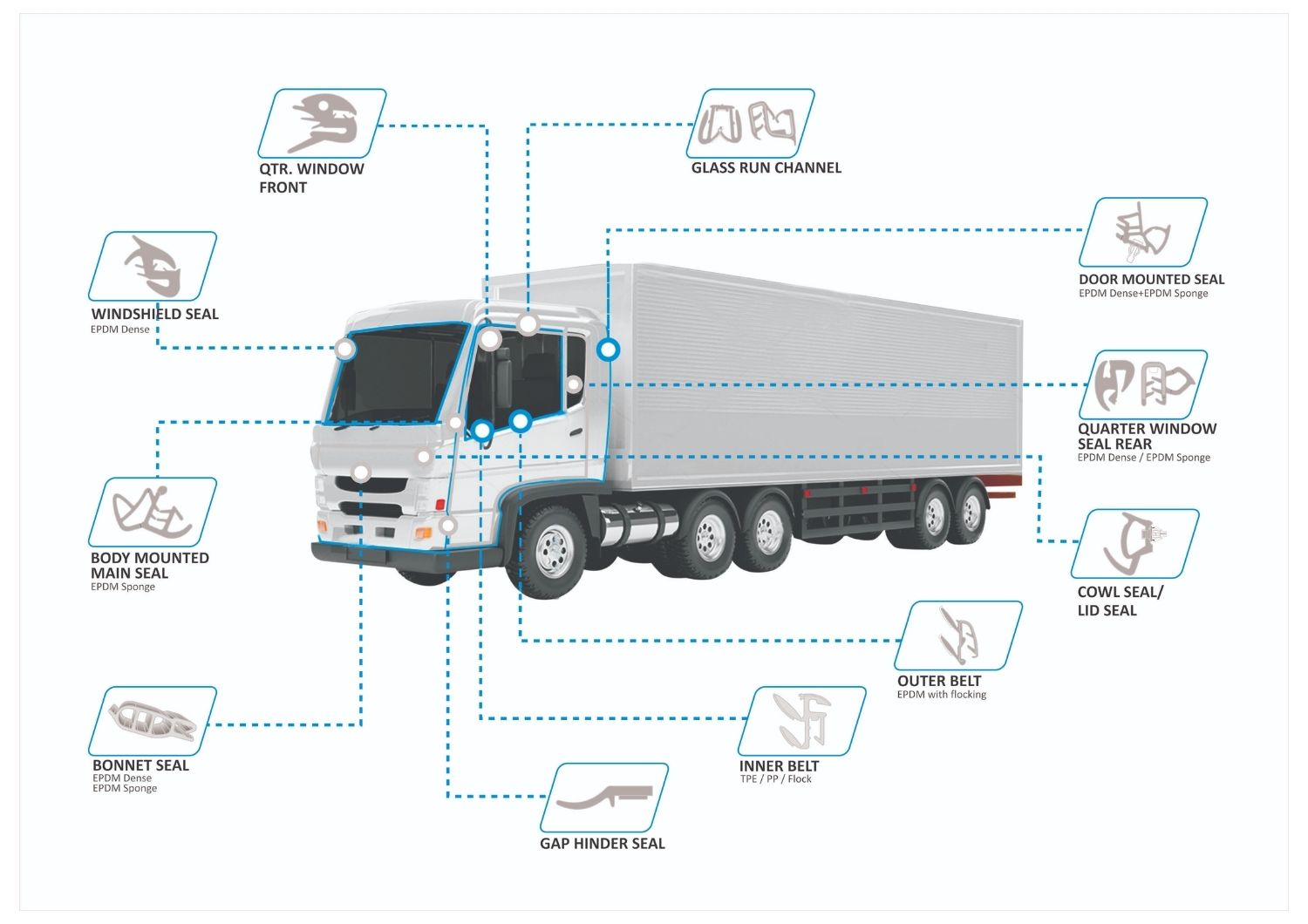

ALP Nishikawa, a 50:50 joint venture with Nishikawa rubber co. of Japan (NRC) is the leading manufacturer of TPE, PVC & EPDM weather strips and Seals in India.

It is a design capable company which can provide wholistic sealing solutions from front bumper to rear bumper in-house. The company has innovation at its core which results in excellence & dynamism in the product offerings. Read More

PRODUCTS

DESIGN & DEVELOPMENT

Product design and engineering division at ALP Nishikawa is capable of designing large product mix of sealing system & the related tooling involved for developing the parts.

Research & Development

ALP Nishikawa's R&D Centre at Lalru, Punjab is Govt. recognized wherein all the research & testing activities are conducted starting from Raw Material (Like Polymer, carbon process oil, etc.) to the final parts taking into consideration the global testing standards.

Product & Process Design

D&D holds primary importance towards assisted and focused growth. For this, ALP Nishikawa has an ultra-modern Design and Development center with self-invented methodologies for optimal reinforcement of structures, digital design and manufacturing of reinforced rubber products.

Innovation

Innovation is the source of value creation for the company. The Innovation Management (IM) program at ANCO integrates the best formal education, ongoing research, and industrial practice to provide our managers that sustain superior business performance and meet customer needs.